Getting My Premier Aluminum Llc To Work

Getting My Premier Aluminum Llc To Work

Blog Article

Premier Aluminum Llc Things To Know Before You Buy

Table of ContentsNot known Facts About Premier Aluminum LlcLittle Known Facts About Premier Aluminum Llc.The Main Principles Of Premier Aluminum Llc The Ultimate Guide To Premier Aluminum Llc

(https://pubhtml5.com/homepage/lekm/)Traditionally, a buyer's primary duty was to find certified and responsive distributors. In some situations, purchasers thought that any type of distributor ready to contractually satisfy the purchase requirement was qualified. Nonetheless, using affordable and unqualified vendors can cause top quality problems, and lost time and money over time. To aid you through the procedure, below are some points to consider when picking the right metal spreading supplier.

For instance, a company that just uses the investment casting process will certainly attempt to sell you on why that process is best for your application. What if making use of the sand spreading procedure is best for you and your requirements? Instead, try to find a vendor that provides a variety of casting processes so the best option for YOU is selected

If collaborating with a single resource for every one of your casting requires is necessary to you, the provider needs to be varied in its capabilities. When integrated with other incorporated capabilities, this can aid simplify and compress the supply base. When picking the right spreading vendor, cautious consideration needs to be offered to quality, solution, and cost.

What Does Premier Aluminum Llc Mean?

Customers increasingly pick spreading providers that have machining capabilities. If the casting vendor discovers a concern during machining, the issue is settled faster with no disagreement over whose fault it is.

Issue or no, incorporated machining streamlines the supply chain and decreases handling time and shipping expense prior to the item makes it to the client. What do you require from your casting vendor? Are you searching for someone to simply deliver a metal element to your front door or do you require more? If you do not have internal metallurgy knowledge, verify that the distributor can give guidance in choosing the appropriate alloy based on your certain application.

Others will go beyond the letter of the PO to aid you conserve money and time. Do you have requirements for both ferrous and non-ferrous alloys? Some foundries are minimal or specialized. Ensure the supplier can satisfy all your product or alloy requirements pop over to this site to get rid of the demand for several providers.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Study the supplier's web site. Talk to a sales rep or service associate.

Light weight aluminum is additionally lightweight and has great deterioration resistance, making it suitable for applications where weight and longevity are necessary factors. Furthermore, aluminum spreading is an affordable technique of manufacturing, as it calls for much less energy and sources than various other methods. Iron casting, on the various other hand, involves pouring liquified iron right into a mold and mildew to produce a wanted form.

Rumored Buzz on Premier Aluminum Llc

Iron casting is also able to stand up to high temperature levels, making it suitable for usage in applications such as engine components and commercial machinery. Iron spreading can be a lot more costly than light weight aluminum spreading due to the higher cost of raw materials and the energy required to melt the iron. When making a decision in between aluminum spreading and iron casting, it is vital to consider the particular requirements of the application.

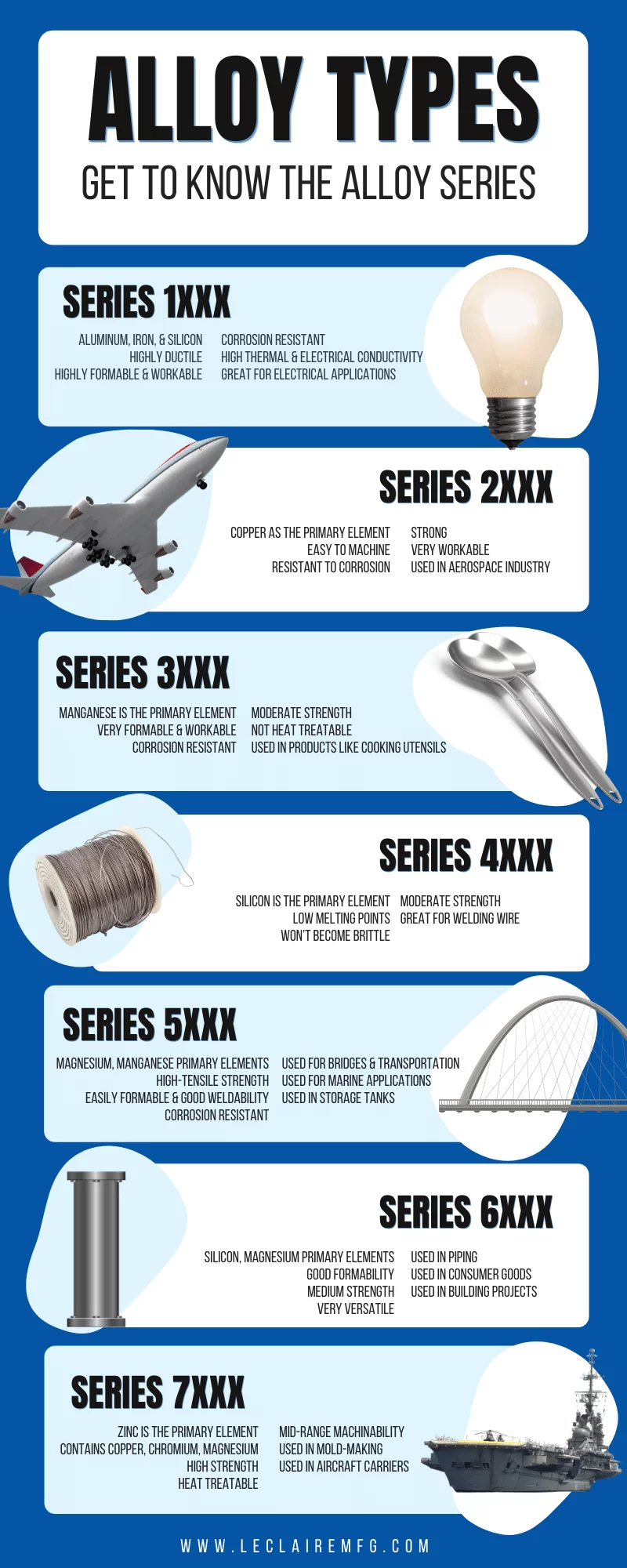

In final thought, both light weight aluminum casting and iron spreading have their own one-of-a-kind advantages and disadvantages. There are three sub-processes that drop under the category of die spreading: gravity die spreading (or irreversible mold and mildew spreading), low-pressure die casting and high-pressure die casting. To obtain to the ended up product, there are 3 key alloys made use of as die casting product to select from: zinc, aluminum and magnesium. Report this page